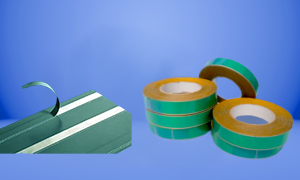

Description

The use of electrochemically treated electrically conductive fabric with pure nickel on all fibers represents an optimal solution for creating an electrical surface in an electrical enclosure that requires protection by non-conductive paint. This treatment generates insulation for the shielding gasket, which must maintain electrical continuity. Therefore, it is suggested to proceed as follows.

Applications

Define the areas on the steel or aluminum electrical enclosure where the conductive gasket and its contact zone will be installed. It is important to follow these steps:

- Remove the protective film from the conductive tape and apply it to the surfaces that require shielding.

- The enclosure can then be painted. The impenetrable mask protects the self-adhesive conductive tape.

- The conductive tape can withstand up to 200°C for about 5 minutes. Once painting is completed and the enclosure has cooled down, the mask can be removed, and the conductive tape will remain securely in place.

Supply

Various sizes are available, as the tapes can be custom-made according to the customer's request, thus allowing for the protection and creation of the conductive part necessary to ensure conduction between the compressive gasket and the fixed part.